Packing Plywood

Views: 1753

Packing plywood is one kind of industrial plywood. It is made from natural wood and has good hardness and bearing strength. Packing plywood is widely used in life today. As its name implies packing plywood is mainly used for packaging. From finished plywood panels, they can make pallets, boxes for goods, machinery, electronic components

Table of contents

1. Specification of Packing Plywood

| Face veneer | Vietnam Veneer, okoume or as required. |

| Back veneer | Vietnam Veneer, okoume or as required. |

| Wood core | Hard core; mixed core |

| Size | 1000 x 2000; 1220 x 2440; or as required. |

| Thickness | 3mm; 6mm; 8mm to 90mm |

| Thickness tolerances | ± 1mm |

| Moisture content | 13° – 15° |

| Density | ≥ 650kg/m3 |

| Wood species | Rubber, Eucalyptus, Styrax, Acacia

Hardwood(Eucalyptus, Forest wood) |

| Glue | UF; MR; E0; E1; E2; Melamine |

| Shaped press | 1 time |

| Hot press | 1 time |

| Cold press | 1 time |

| Surface sanding | or as required |

2. How to produce Packing PLywood by Kim Global

- Firstly, the main material – the trees are peeled then put into the sawing machine to cut into logs of suitable length.

- Secondly, the worker put the logs into peeling machine to make very thin slices called veneers. There are also some grades of veneer, according to the quality, they classify into: A, B and C grade

- Thirdly, they will dry the veneers: There are 2 methods to dry veneers. In the first method: they use machine by putting veneers into drying machine, set the time and wait till it reach the suitable moisture. The second method: Manual drying by spreading the veneers on the drying platform and dry until the moisture is reached.

- Glue: The veneers are spread by glue in 2 sides before being put in the table in the next step

- According to the thickness of the sheet, the worker will choose the suitable thickness of the veneer and the quantity of layers. They will put 1 layer vertically, next layer horizontally and so on to get stronger structure.

- The sawing machine will make the sheets in the right size.

- At last, the workers will choose the sheets that meet the requirements of thickness, structure…etc and pack the sheets to ship to the customer.

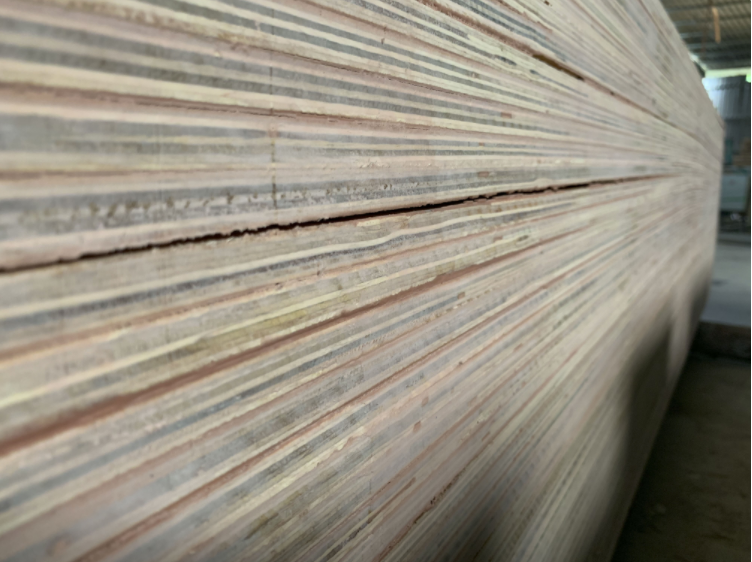

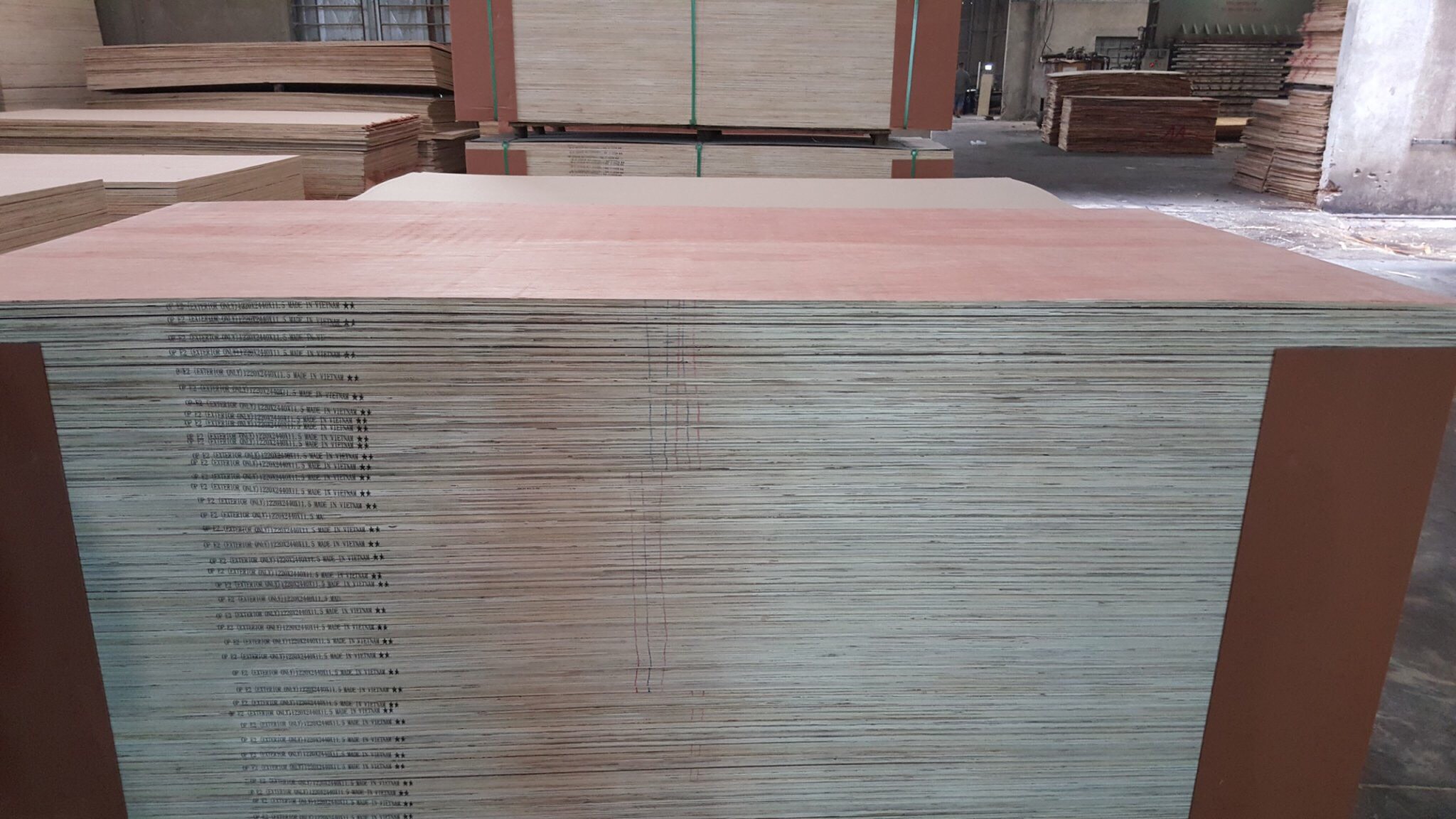

3. Packing Plywood images